- Overview

- Product Description

- Product Parameters

Basic Info.

Packaging & Delivery

Product Description

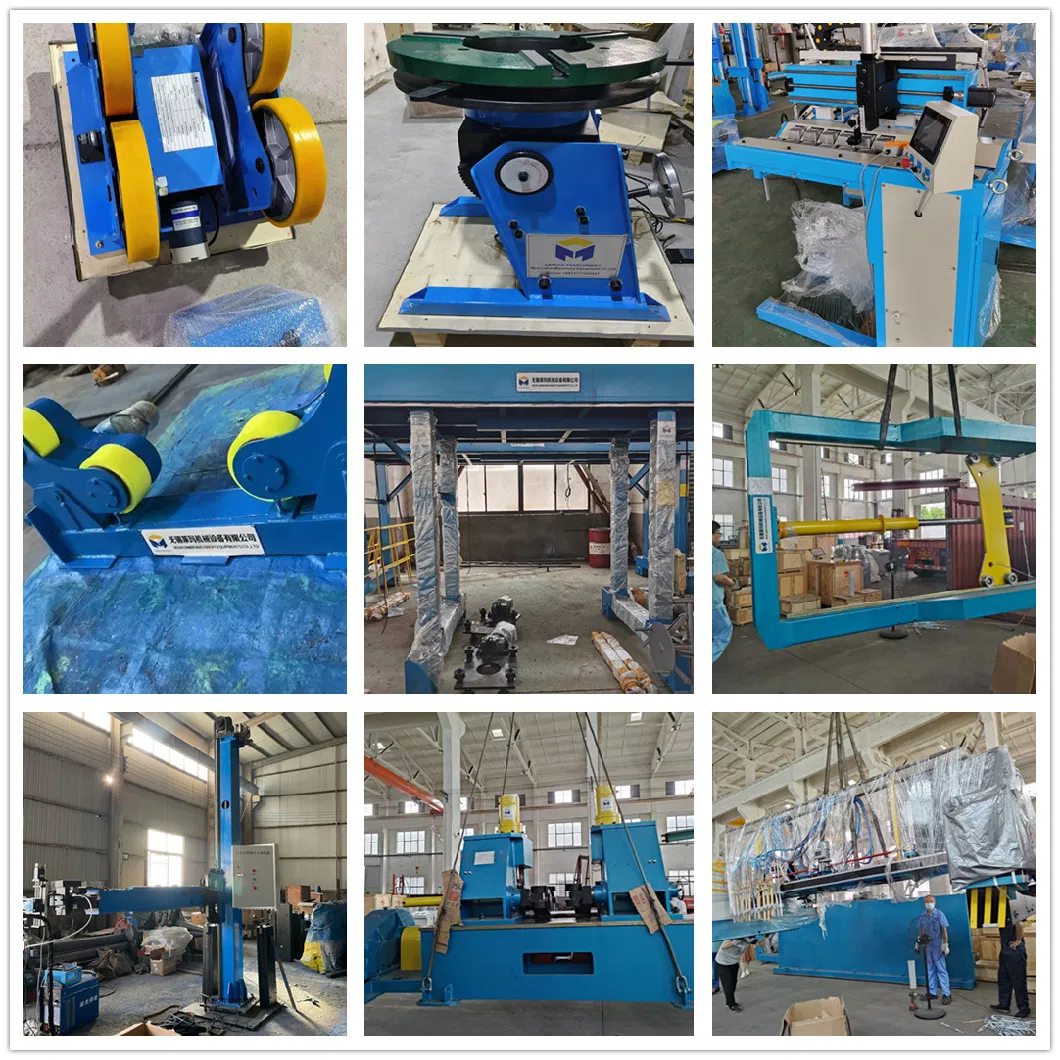

Heavy duty steel wheel Pressure Vessel Welding Rotator

80T Loading weight Tank Rolls Rotator with Self Adjustment has the function of supporting and moving welding workpieces.It can provide stable support for pipes, tanks, and round workpieces, making the welding process more accurate and efficient.

At the same time, it has the function of adjusting the height and adjusting the angle through bolt and screw to adapt to workpieces of different sizes and shapes.

1. The clamping parts of the drum, shaft and gear are all cut from 45# standard profiles or metal forgings to meet the bearing life and effectively promote the rotation of the drum.

2. AC variable frequency motor (international brand).

3. Spherical roller bearings, strong load-bearing capacity and impact resistance

4. All shaft and gear parts have been quenched and tempered. Especially the tempering and quenching of gear parts.

5. The welding base of the Turning rotator is welded from plates. Sufficient strength to ensure long-term use.

6. All shaft holes are processed by CNC boring machines, and the gear accuracy is level 7 to ensure accurate dimensions.

7. The electronic control system mainly consists of an electrical control box and a manual control box. The frequency conversion control system adopts domestic ENC control, and the hand control box connection line adopts imported ultra-soft wires and cables to ensure reliable use.

8. The control box and driving wheel frame of Wind Towers Fit up Turning rotators are installed as one unit for easy transportation.

| Model | Max loading weight(kg) | Suitable work range(mm) | Rubber wheel diameter and width(mm) | Metal wheel diameter and width(mm) | Roller linear speed(m/h) | Power | Distance Adjustment method |

| ZTG-5 | 5000 | 250-2300 | Ф250*100 | 2*Ф240*20 | 6-60 | 2*0.37 | Manual/screw adjustable |

| ZTG-10 | 10000 | 300-2800 | Ф300*120 | 2*Ф290*25 | 2*0.55 | ||

| ZTG-20 | 20000 | 500-3500 | Ф350*120 | 2*Ф340*35 | 2*1.1 | ||

| ZTG-40 | 40000 | 600-4200 | Ф400*120 | 2*Ф390*45 | 2*1.5 | ||

| ZTG-60 | 60000 | 750-4800 | Ф450*120 | 2*Ф440*60 | 2*2.2 | Screw/bin adjustable | |

| ZTG-80 | 80000 | 850-5000 | Ф500*120 | 2*Ф490*70 | 2*3 | ||

| ZTG-100 | 100000 | 1000-5500 | Ф500*120 | 2*Ф490*80 | 2*3 | ||

| ZTG-150 | 150000 | 1100-6000 | / | Ф620*220 | 2*4 | ||

| ZTG-250 | 250000 | 1100-7500 | / | Ф660*260 | 2*5.5 | ||

| ZTG-400 | 400000 | 1100-7500 | / | Ф750*320 | 2*7.5 | ||

| ZTG-500 | 500000 | 1100-7500 | / | Ф750*400 | 2*11 | ||

| Speed regulation mode -- frequency conversion stepless speed regulation or DC stepless speed regulation | |||||||

| Type | Features | Application range of welding roller rotator |

| Steel wheel | Strong bearing capacity and easy to manufacture | Typically used for heavy duty offshore wind power pipes and work-piece requiring preheat treatment and roller racks rated greater than 60 tons |

| Rubber wheel | The steel wheel is covered with a rubber wheel, with high friction and stable transmission, suitable for stainless steel pipe fittings | Generally used for weldments and non-ferrous metal containers under 10 tons |

| Combination wheel | The steel wheel is combined with the rubber wheel, the bearing capacity is higher than that of the rubber wheel, and the transmission is stable | Generally used for welding parts of 10~60 tons |

| Track wheel | The large area of crawler and the weldment are in contact, which is beneficial to prevent the deformation of thin-walled workpieces, and the transmission is stable but the structure is complicated. | For light-duty, thin-walled and large-diameter weldments and non-ferrous metal vessels |