Basic Info.

Model NO.

PL2

Welding Turning Rolls Type

Fixed and Lift

Welding Tilter Type

Flexible Combination

Condition

New

Tons

Pl251

Transport Package

Nude

Specification

1200-2000

Trademark

DESAN

Origin

China

HS Code

84688000

Production Capacity

1000

Product Description

Welding positioner is mainly used to placed the work piece in the best position for welding and assembling with the work bench elevating, turning, tilting , its series includes tilting, head and tail stocks ,elevating ,and double turning positioner, cradle type. The positioner can be supplied for interfacing with robot or welding manipulators ,to realize the welding automation. At the same time we can design and customize various type of special positioner according to the technological requirement and different work piece given by the customer.

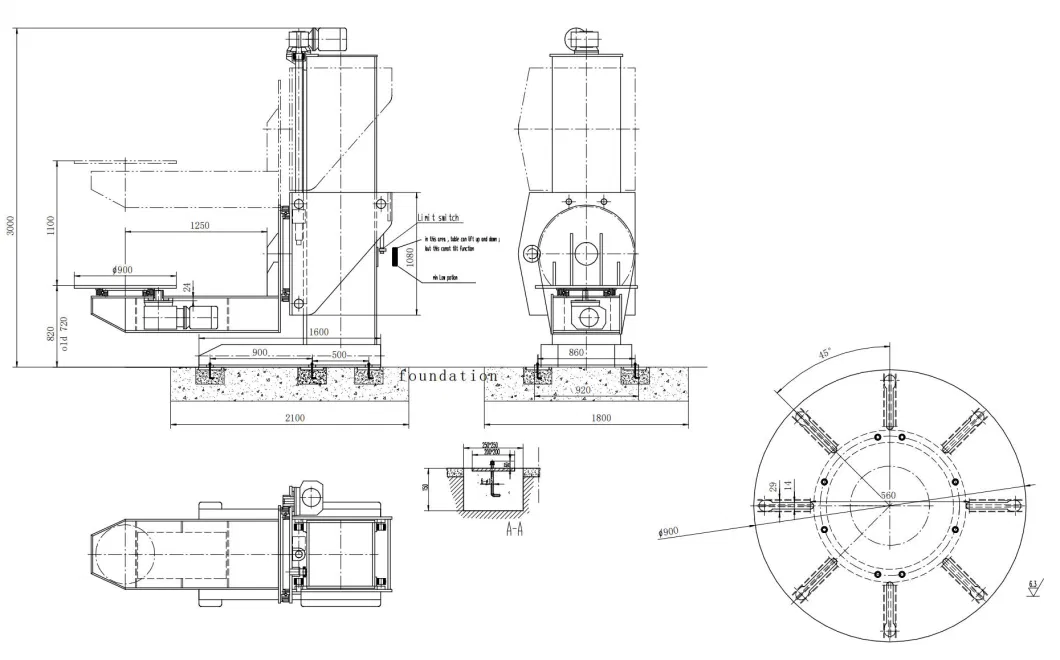

Max load capacity: 2500 kg

Lift effective distance : 1100mm

Rotation table dia. 1200mm

Rotation eccentricity: 100mm

Tilting center ectrioid height:280mm

Tilting speed: 0.8rpm

Elevating speed : 0.45m/min

Total power :5kw

Dwp type elevating welding positioner is mainly used for solving problems of high position, also can weld seam provide low installation position, make the workpiece clamp and fix more easily or double , including single revolve and double revolve frame , can make the work piece on better welding position.

+ Ball screw (or chain), with security nut, safe and reliable.

+ High strength, cooperate, inverter, no impact on the smooth.

+ Using electrical synchronous on elevating action , easily fast installation, commissioning, maintenance convenience.

Notes:

a) For more details of Positoner capacity see sheets ,

b) For ordering an adjustable height positioner add the prefix AH. Available for models WP 5 and smaller

c) Control cabinet includes: power indicator, speed indicator, speed adjustment, overturn (tilt) up and down, forward and reverse rotation, stop, fault & reset

d) Remote control box allows adjustment of table rotating speed (digital display in RPM/min), forward and reverse rotation, and stop

e) "T" shaped channels on work table surface

f) Shot blasted frame at SA 2 ½ before being painted

g) Custom built Welding Positioners available

h) The information contained in this brochure is intended to beaccurate. However the manufacturer retain the rights to make changes in design which may not be include herein

Optional:

i) Foot control pedal for changing rotation direction and stop,

ii) variable speed on tilt

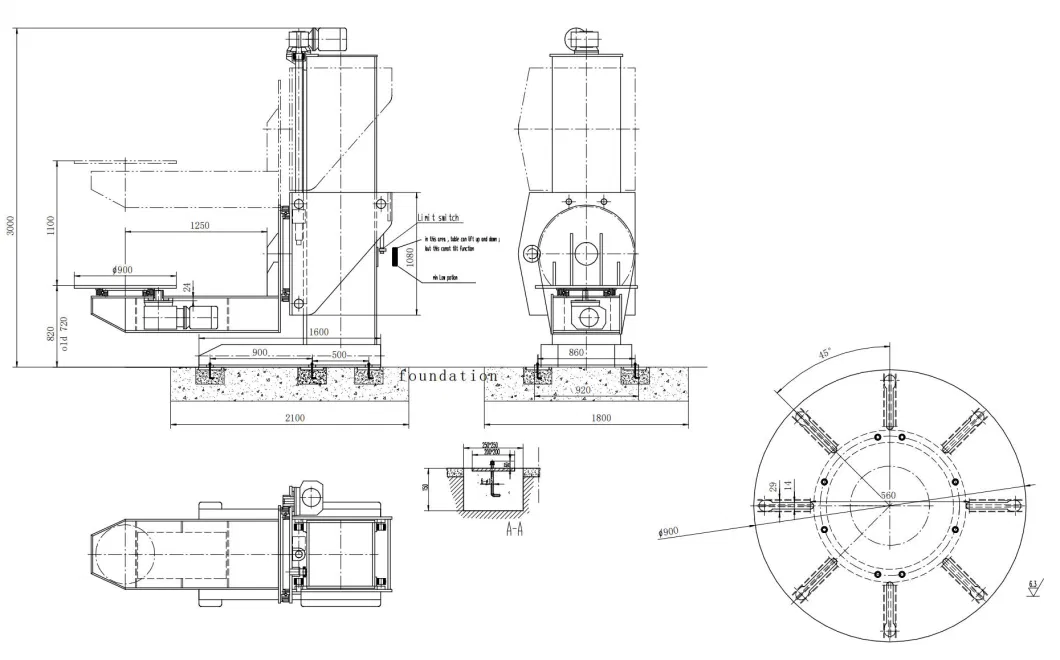

Max load capacity: 2500 kg

Lift effective distance : 1100mm

Rotation table dia. 1200mm

Rotation eccentricity: 100mm

Tilting center ectrioid height:280mm

Tilting speed: 0.8rpm

Elevating speed : 0.45m/min

Total power :5kw

Dwp type elevating welding positioner is mainly used for solving problems of high position, also can weld seam provide low installation position, make the workpiece clamp and fix more easily or double , including single revolve and double revolve frame , can make the work piece on better welding position.

+ Ball screw (or chain), with security nut, safe and reliable.

+ High strength, cooperate, inverter, no impact on the smooth.

+ Using electrical synchronous on elevating action , easily fast installation, commissioning, maintenance convenience.

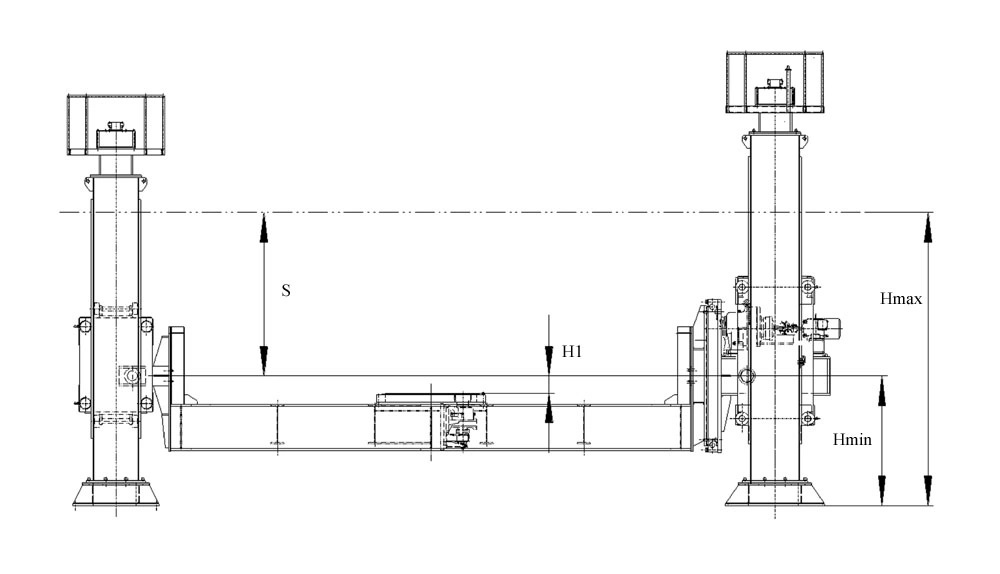

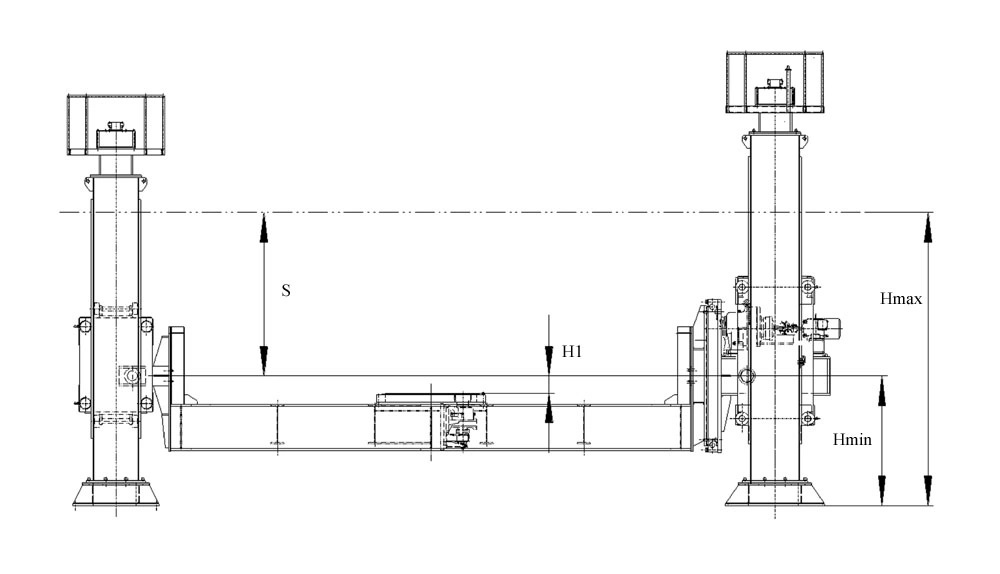

| Model | Rated load Cap(tons) | Tilting | Elevating | Table | ||||||

| DWP Series | speed (rpm) | gravity centre dist. (mm) | speed (m/min) | Min ctr dist. Hmin (mm) | Max ctr. Dist.Hmax (mm) | Elevating stroke S(mm) | Max centroid | Speed (rpm) | Table surf to ctr H1(mm) | |

| DWP1 | 1 | 2 | 200 | 1 | 800 | 1600 | 800 | 200 | N/A | N/A |

| DWP2 | 2 | 2 | 200 | 1 | 800 | 1600 | 800 | 200 | N/A | N/A |

| DWP3 | 3 | 1.8 | 200 | 1 | 800 | 1600 | 800 | 300 | N/A | N/A |

| DWP4 | 4 | 1.5 | 200 | 1 | 800 | 1600 | 800 | 300 | N/A | N/A |

| DWP5 | 5 | 1.5 | 200 | 1 | 1000 | 2000 | 1000 | 300 | N/A | N/A |

| DWP6 | 6 | 1.5 | 200 | 1 | 1000 | 2000 | 1000 | 300 | N/A | N/A |

| DWP8 | 8 | 1.5 | 200 | 1 | 1000 | 2000 | 1000 | 300 | N/A | N/A |

| DWP10 | 10 | 1 | 300 | 1 | 2000 | 3000 | 1000 | 150 | 0.05-0.5 | 100 |

| DWP20 | 20 | 1 | 300 | 1 | 2000 | 3000 | 1000 | 150 | 0.05-0.5 | 100 |

| DWP30 | 30 | 0.5 | 450 | 0.5 | 2000 | 3500 | 1500 | 150 | 0.05-0.5 | 150 |

| DWP50 | 50 | 0.5 | 450 | 0.5 | 2000 | 3500 | 1500 | 150 | 0.05-0.5 | 150 |

| DWP80 | 80 | 0.2 | 600 | 0.2 | 2600 | 4100 | 1500 | 250 | 0.02-0.2 | 250 |

| Model | Rated load Cap(tons) | Power (kW) | Max Gravity height (mm) | Max centroid Eccentricity (mm) | Table | 90 Max Rotation Æ (mm) @ 90degree | Tilt Angle (degree) | Dimensions | Weight (tons) | ||||

| EWP Series (SHB ) | Rotation | Tilt | Speed (RPM) | Diameter ΦD(mm) | |||||||||

| Rotation (variable) | Tilt (constant) | L*W*H (mm) | Emin-max/p(m) | ||||||||||

| EWP 1 | 1 | 1.1 | 1.5 | 250 | 150 | 0.12 - 1.2 | 0.67 | 900 | 1500 | 0-135 | 1210*1500*1670 | 1.1*1.7/0.15 | 1.2 |

| EWP 2 | 2 | 1.1 | 1.5 | 300 | 150 | 0.05 - 0.5 | 0.23 | 1200 | 2000 | 0-135 | 1780*1320*1800 | 1.2*1.8/0.15 | 1.6 |

| EWP 4 | 4 | 1.5 | 2.2 | 300 | 150 | 0.05 - 0.5 | 0.23 | 1400 | 2100 | 0-120 | 2140*1500*2100 | 1.3*1.9/0.15 | 2.8 |

| EWP 6 | 6 | 2.2 | 3 | 300 | 150 | 0.05 - 0.5 | 0.14 | 1500 | 2500 | 0-120 | 2760*1630*2600 | 1.6*2.4/0.2 | 5.0 |

| EWP 8 | 8 | 2.2 | 4 | 400 | 200 | 0.02-0.2 | 0.14 | 1600 | 2800 | 0-120 | 2950*1850*2800 | 1.7*2.6/0.22 | 6.5 |

| EWP 10 | 10 | 3 | 5.5 | 400 | 200 | 0.02 - 0.2 | 0.14 | 1800 | 3000 | 0-120 | 3300*2000*3100 | 1.9*2.9/0.24 | 7.8 |

| EWP 15 | 15 | 3 | 5.5 | 400 | 200 | 0.02-0.2 | 0.1 | 2000 | 3200 | 0-120 | 3600*2200*3450 | 2.1*3.2/0.25 | 12 |

| EWP 20 | 20 | 4 | 7.5 | 400 | 200 | 0.02 - 0.2 | 0.1 | 2200 | 3400 | 0-120 | 4000*2400*3800 | 2.3*3.5/0.3 | 18 |

Notes:

a) For more details of Positoner capacity see sheets ,

b) For ordering an adjustable height positioner add the prefix AH. Available for models WP 5 and smaller

c) Control cabinet includes: power indicator, speed indicator, speed adjustment, overturn (tilt) up and down, forward and reverse rotation, stop, fault & reset

d) Remote control box allows adjustment of table rotating speed (digital display in RPM/min), forward and reverse rotation, and stop

e) "T" shaped channels on work table surface

f) Shot blasted frame at SA 2 ½ before being painted

g) Custom built Welding Positioners available

h) The information contained in this brochure is intended to beaccurate. However the manufacturer retain the rights to make changes in design which may not be include herein

Optional:

i) Foot control pedal for changing rotation direction and stop,

ii) variable speed on tilt