Basic Info.

Model NO.

BWJ-2T

Tilting Angle

0-120°

Voltage

380-440V

Condition

New

Model

Bwj-2t

Positioner Function

Welding Platform Rotary Positioner

Loading Weight

2000kg

Rotary Table Size

1000mm

Rotating Speed of Table

0.25rpm

Tilt Angle

360 Degree

Lead Time

10 Days

Turtable Diameter

1400mm

Rotating Motor

1.1kw

Tilt Motor

2.2kw

Warranty

1 Year

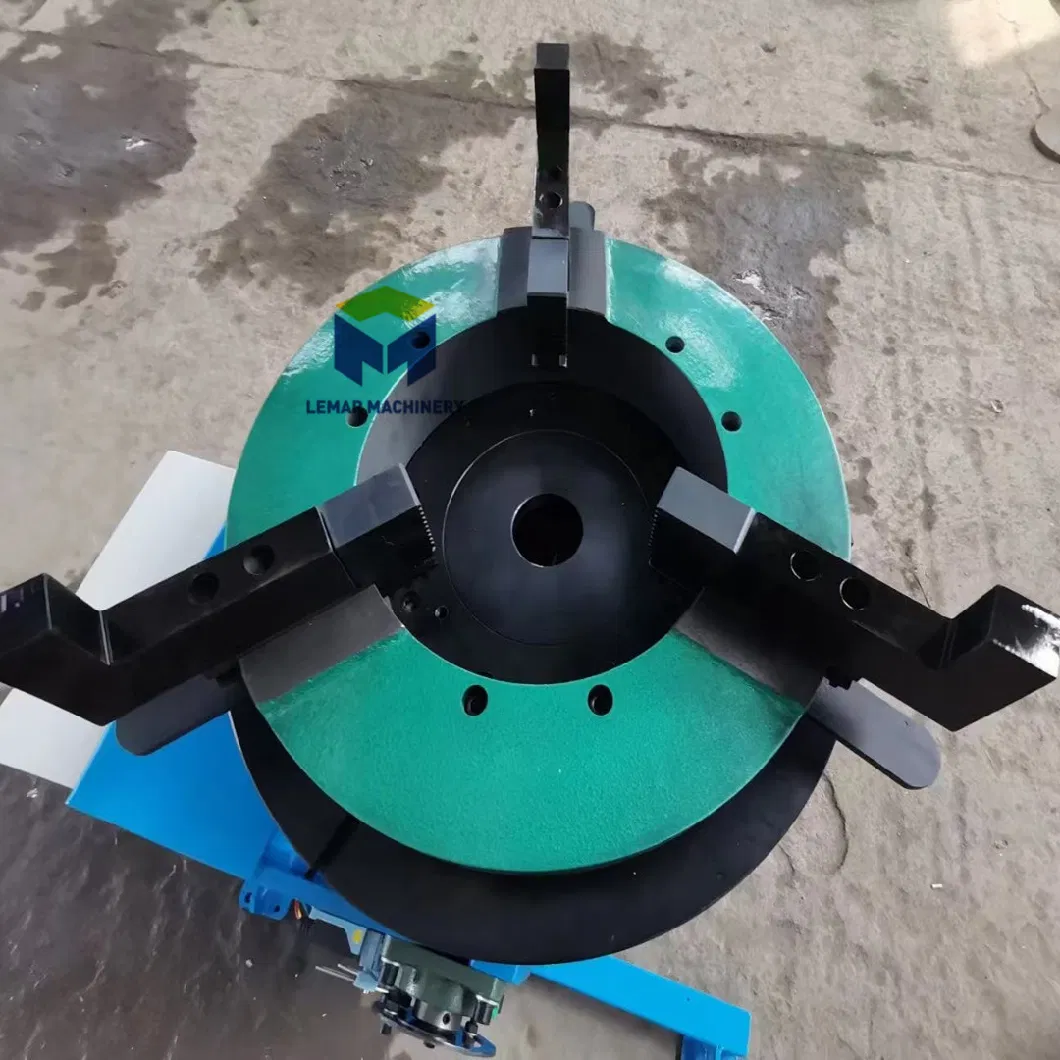

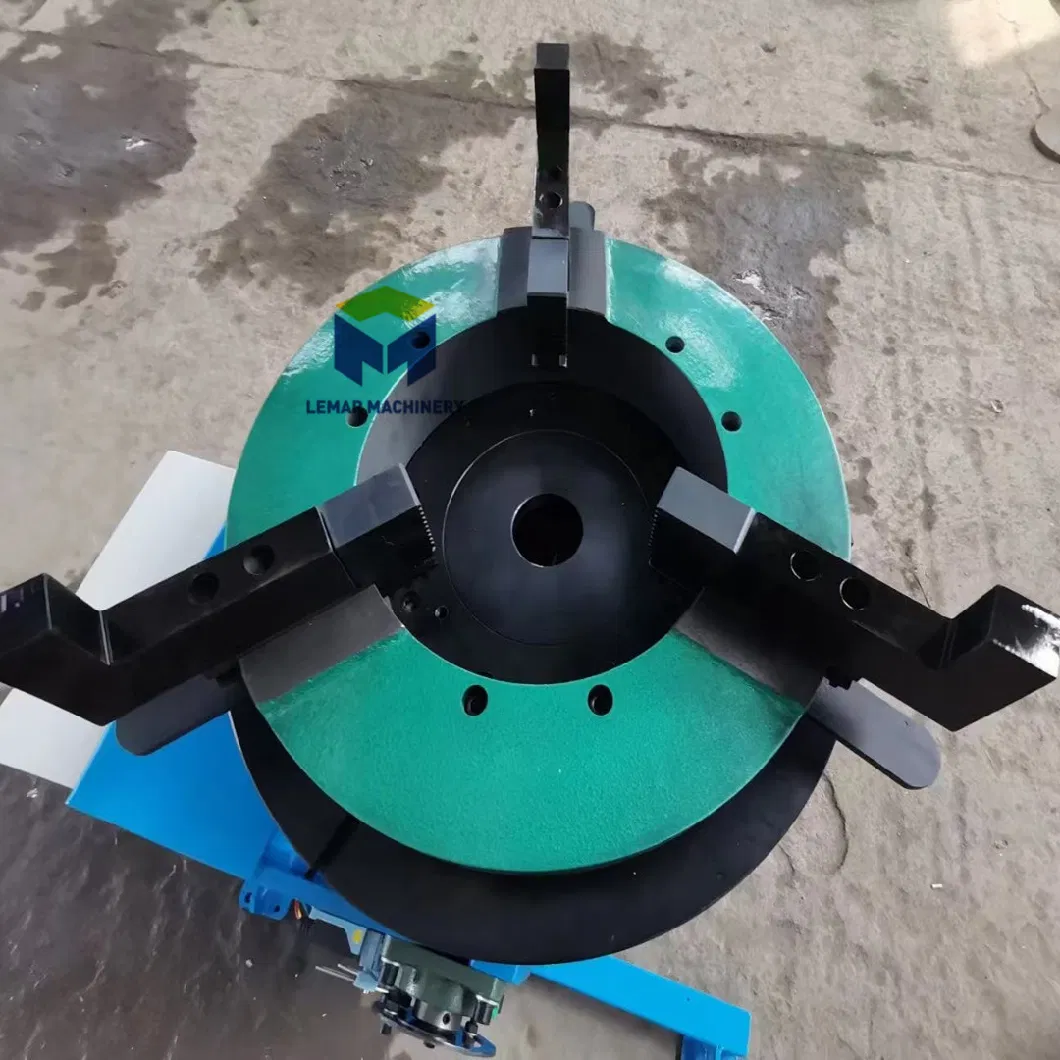

Welding Chuck

3 Jaw or Customized

Turning for

Tank Pipe Flange Automatic Welding

Working Together with

Welding Manipulator/TIG MIG Welding Machine

Customized

Yes

Transport Package

Wooden

Trademark

Lemar

Origin

Wuxi, China

HS Code

8428909090

Production Capacity

3000PCS/Year

Packaging & Delivery

Package Size

170.00cm * 180.00cm * 75.00cm

Package Gross Weight

930.000kg

Product Description

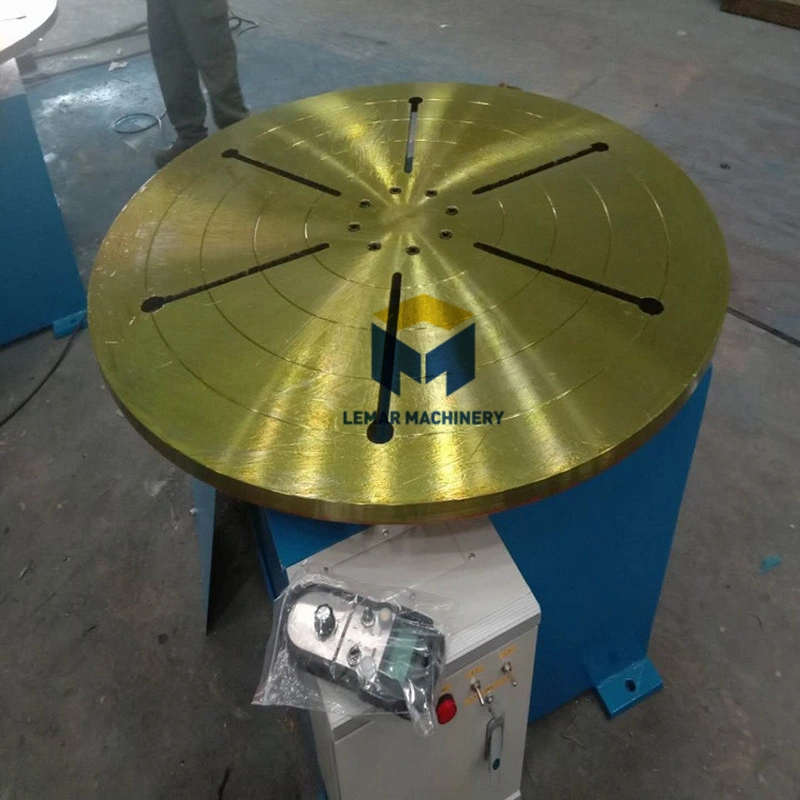

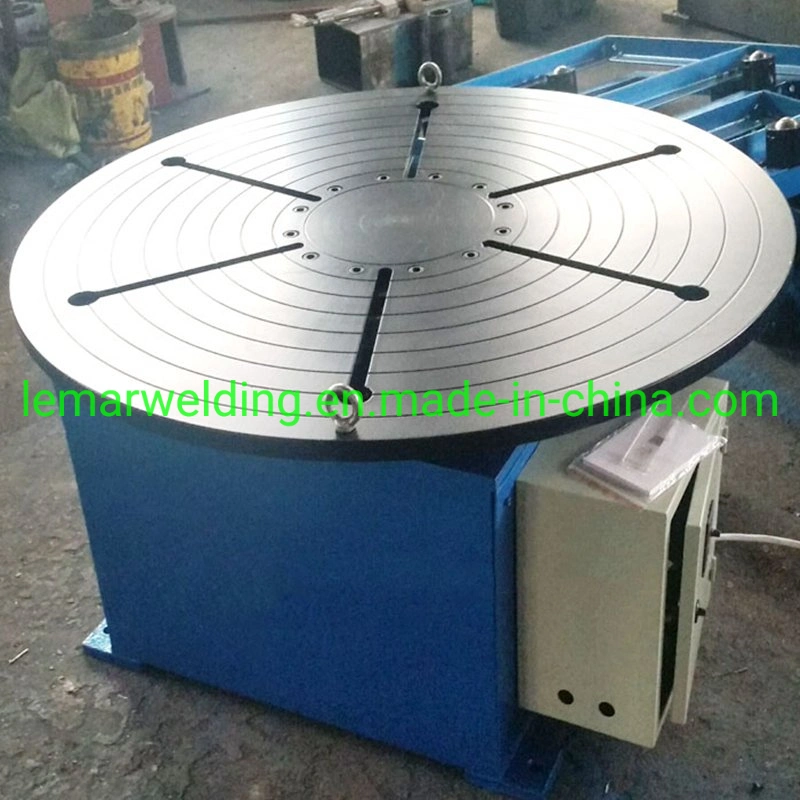

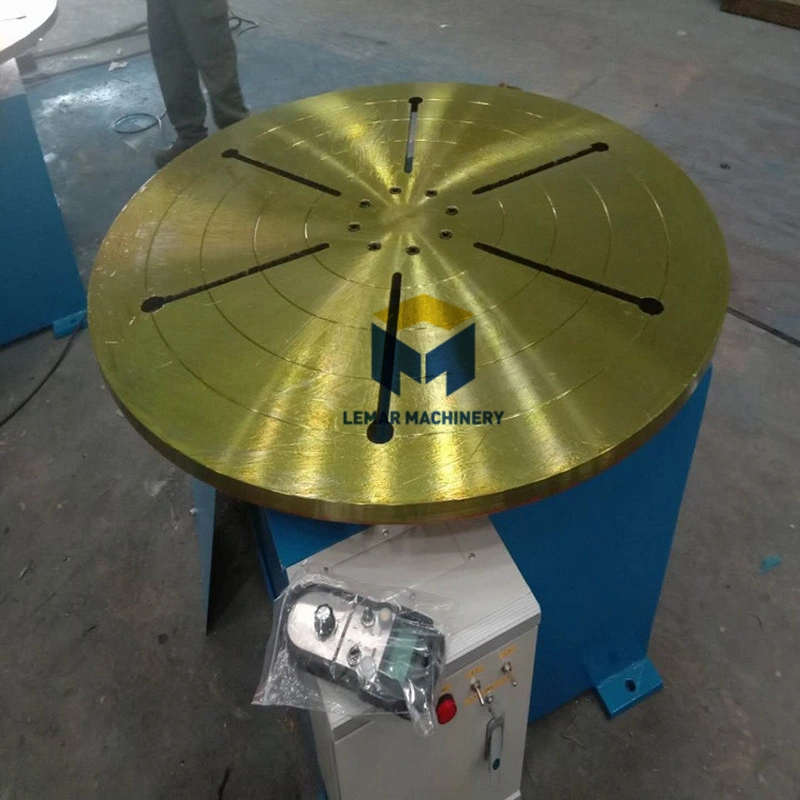

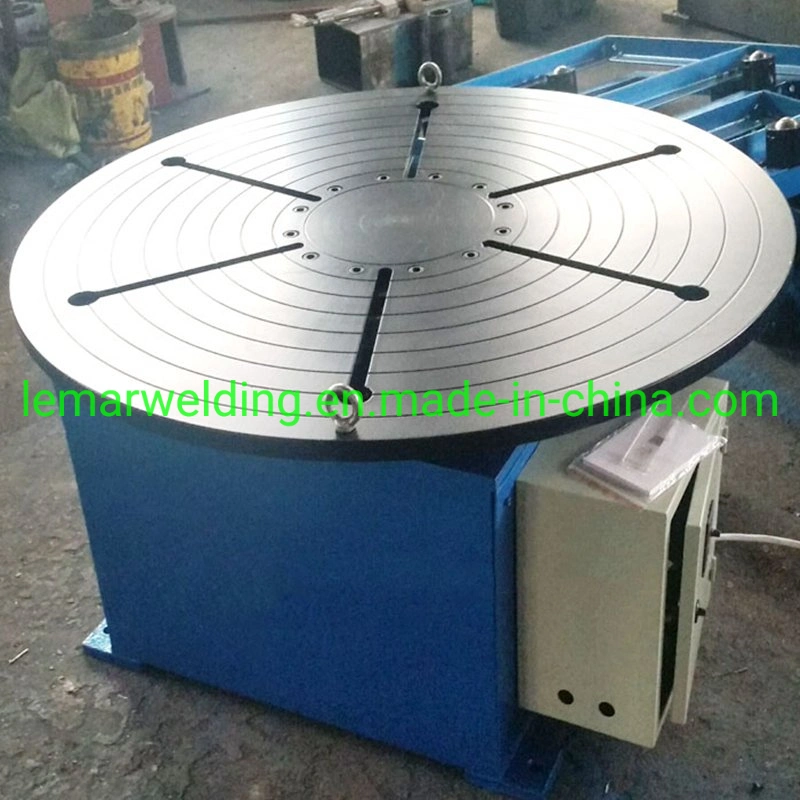

Motorized welding turntable rotary table welding positioner 2000KG Loading capacity

What is a pipe welding positioner?

A mechanical tool known as a pipe welding positioner is employed in the welding industry to hold and rotate pipes in order to position and angle welds properly.

Welders can work on longer, heavier, or larger pipes thanks to this, which boosts their efficiency and accuracy. A base, a rotating platform, a mounting mechanism, and a control panel make up a pipe welding positioner.

They can be utilized in stick welding, TIG welding, MIG welding, or submerged arc welding, among other pipe welding applications.

Specification of 2000kg Automatic rotary welding positioner:

Why need welding chuck for positioner?

Why need welding chuck for positioner?

Because it enables the workpiece to be safely held in place and turned throughout the welding process, a welding chuck is crucial for a positioner.

As a result, the workpiece can be positioned at the best angle and orientation for the welder to reach, resulting in more reliable and high-quality welds.

Without a welding chuck, the workpiece could move around or shift while being welded, resulting in poor or uneven welds.

Additionally, utilizing a welding chuck contributes to increased safety because it lessens the possibility of an accidently jostling or bumping the workpiece or welder when welding.

How many different types of pipe welding chucks are there?

How many different types of pipe welding chucks are there?

For pipe welding positioners, a variety of welding chucks are offered, including:

1. Three-jaw self-centering chucks may be adjusted to fit a variety of pipe sizes, making them perfect for handling pipes of different diameters.

2. Four-jaw independent chucks are ideal for retaining pipes with asymmetrical or non-round forms. For a tight grip, each jaw can be separately adjusted.

3. Welding lathe chucks: These chucks can safely hold and rotate pipes during welding. They are intended for use with lathe-style positioners.

4. Collet-style chucks: These chucks offer a firm grip without crushing thin-walled or small-diameter pipes, making them perfect for holding them.

5. Vacuum chucks: Using suction instead of clamps or other mechanical fasteners, these chucks hold pipes in position while welding.

Why choose Wuxi Lemar?What can Lemar do for clients?

Why choose Wuxi Lemar?What can Lemar do for clients?

Our Product

Our company Wuxi Lemar is mainly engaged in research and development, manufacture and sale, CNC Plasma cutting machine and Automatic welding equipment such as H-beam welding production line (light type, heavy type), box beam welding production line, horizontal assembly&welding production line,adjustable welding rotator, self-aligning welding turning rolls,seat type welding positioner,robotic welding turning assembly positioner,Customized positioners,3 jaw 4 jaw welding chuck,Straight seam welding machines,Circular seam welding machines,Column and boom TIG MIG SAW Tank and vessel welding manipulators,etc,

Our Product Application

The products are widely used in steel structure, shipbuilding, bridge building, boiler, chemical industry, metallurgy, electrical power industries etc.

Our Certificate

We have passed the ISO CE SGS testing standard, besides, our machine have honor to won many patents, like H-beam manufacturing equipment patents, welding positioner,welding rotator,column and boom rotate welding manipulator patents and etc.

Our machines have been exported to USA,UK,Canada,Russia,Poland, France,Kazakhstan, Pakistan, Bulgaria, Colombia,Brazil,etc.

Our service

All of our machines have one year warranty,we are 24 hours online for after sales service,we can send engineers to client's sites to resolve problems.

What is a pipe welding positioner?

A mechanical tool known as a pipe welding positioner is employed in the welding industry to hold and rotate pipes in order to position and angle welds properly.

Welders can work on longer, heavier, or larger pipes thanks to this, which boosts their efficiency and accuracy. A base, a rotating platform, a mounting mechanism, and a control panel make up a pipe welding positioner.

They can be utilized in stick welding, TIG welding, MIG welding, or submerged arc welding, among other pipe welding applications.

Specification of 2000kg Automatic rotary welding positioner:

| Model | BWJ-2T |

| Max loading weight | 2000kg |

| Table diameter | 1200mm-1400mm |

| Rotating speed | 60°/s |

| Repeatability | ±1.0arc/m |

| Rotating angle | ±360° |

| Eccentricity | <=200mm |

| Center of gravity | <=200mm |

| Rotate motor | 1.1kw |

| Tilt motor | 2.2kw |

Because it enables the workpiece to be safely held in place and turned throughout the welding process, a welding chuck is crucial for a positioner.

As a result, the workpiece can be positioned at the best angle and orientation for the welder to reach, resulting in more reliable and high-quality welds.

Without a welding chuck, the workpiece could move around or shift while being welded, resulting in poor or uneven welds.

Additionally, utilizing a welding chuck contributes to increased safety because it lessens the possibility of an accidently jostling or bumping the workpiece or welder when welding.

For pipe welding positioners, a variety of welding chucks are offered, including:

1. Three-jaw self-centering chucks may be adjusted to fit a variety of pipe sizes, making them perfect for handling pipes of different diameters.

2. Four-jaw independent chucks are ideal for retaining pipes with asymmetrical or non-round forms. For a tight grip, each jaw can be separately adjusted.

3. Welding lathe chucks: These chucks can safely hold and rotate pipes during welding. They are intended for use with lathe-style positioners.

4. Collet-style chucks: These chucks offer a firm grip without crushing thin-walled or small-diameter pipes, making them perfect for holding them.

5. Vacuum chucks: Using suction instead of clamps or other mechanical fasteners, these chucks hold pipes in position while welding.

Our Product

Our company Wuxi Lemar is mainly engaged in research and development, manufacture and sale, CNC Plasma cutting machine and Automatic welding equipment such as H-beam welding production line (light type, heavy type), box beam welding production line, horizontal assembly&welding production line,adjustable welding rotator, self-aligning welding turning rolls,seat type welding positioner,robotic welding turning assembly positioner,Customized positioners,3 jaw 4 jaw welding chuck,Straight seam welding machines,Circular seam welding machines,Column and boom TIG MIG SAW Tank and vessel welding manipulators,etc,

Our Product Application

The products are widely used in steel structure, shipbuilding, bridge building, boiler, chemical industry, metallurgy, electrical power industries etc.

Our Certificate

We have passed the ISO CE SGS testing standard, besides, our machine have honor to won many patents, like H-beam manufacturing equipment patents, welding positioner,welding rotator,column and boom rotate welding manipulator patents and etc.

Our machines have been exported to USA,UK,Canada,Russia,Poland, France,Kazakhstan, Pakistan, Bulgaria, Colombia,Brazil,etc.

Our service

All of our machines have one year warranty,we are 24 hours online for after sales service,we can send engineers to client's sites to resolve problems.